Laser marking is essential in businesses and personal households for its accuracy, precision and non-contact form of design. Although it has many applications, the process has many associated hazards and personal injury, such as skin and eye damage. Therefore, operators must follow some safety guidelines when laser marking. There are a variety of controls you can use with laser marking, and in this article, you'll learn safety guidelines for preventing and controlling laser marking hazards.

Common Laser Hazards

The level of danger experienced by the operator depends on the laser beam wavelength and exposure time. Common hazards that people encounter include:

1. Eye Trauma

This is the most serious of all the risks associated with lasers, as critical parts of the body such as the cornea, lens and retina are easily affected. Therefore, operators must protect themselves as damage to these components can result in partial or total loss of vision. Also, depending on the part of the eye, it can lead to photokeratitis, cataracts, eyelid cancer, or retinal damage.

2. Skin Damage

Direct exposure to the laser beam and specular reflections can cause skin damage. The extent of the burn depends on the exposure time, wavelength and laser power, and the area of exposure. Operators must protect their skin from radiation, as skin damage can worsen, dry, peel, itch, and become redder or darker.

3. Fire Hazard

In addition to presenting health risks, lasers can cause fires and endanger employees. Operators need to be especially careful when working with Class IV lasers. Of all classes of lasers, Class IV poses a fire safety threat to all classes of lasers as they can ignite combustible materials by direct beam or any reflection.

Safety Guidelines to Follow When Laser Marking

Safety guidelines allow you to control the laser beam and prevent hazards and injuries. There are three main categories of security guidelines you can use, as described below:

Administrative Control

This control is an essential part of every business or company that uses a laser marking machine to protect their people, workspace and equipment

Work with Highly Trained Personnel

Unskilled operators can misuse laser markers, putting them at risk of injury as discussed earlier. Before hiring an individual, make sure they have the necessary laser marking training and instruction.

Proper training can reduce accidental exposure to laser beams. In addition, equipment is not damaged because skilled operators can align the laser beam and detect faulty equipment early.

Put up warning signs

Laser Safety Signs Post warning signs where laser marking is used to ensure employees and visitors are aware of the risks. The sign should also include certain types of reflective clothing that the operator should not wear.

Correct Use and Maintenance of Laser Marking Machine

To prevent accidents, install modules that allow the correct use and maintenance of the laser marker. For example, ensure adequate ventilation to prevent fire outbreaks - properly remove residues and debris to maintain a clean environment and marking process. Also, use an exhaust system to eliminate smoke production and use a fire extinguisher in the event of a fire.

Use Only Approved Materials

Some materials emit harmful and corrosive fumes during the marking process, putting operators and other employees at risk. Therefore, businesses should only label compatible materials.

Operator Control

The controls here contain safety guidelines for people and equipment. Non-professional users cannot operate the laser engraver machine

Protecting Mask

Shields are an effective way to control and prevent laser marking hazards and injuries. They work by isolating machines and parts from the environment, thereby reducing exposure to laser beams and reducing the risks associated with such exposures.

Create a shield around the marked head. Doing so protects the operator and other employees from accidental reflected light. Materials used for shielding should have suitable thermal and reflective properties to block reflected laser light.

Use Personal Protective Equipment (PPE)

PPE may be required when engineering controls are insufficient to prevent direct or reflected beams from exceeding maximum allowable limits. However, the use of personal protective equipment as the sole control measure may not be effective when using Class IV lasers.

Protection Goggle

Safety glasses protect your eyes from laser marking machines, especially class III and IV lasers. Examples of protective eyewear include laser safety goggles, face shields, or glasses with specific filter materials.

Each laser marking system has a pair of laser safety glasses specific to its wavelength. Common ones include:

- A CO2 laser with a wavelength of 10.6 microns is used with glasses with an optical density of 5-7.

- Fiber lasers with a wavelength of 1090 nanometers are used with glasses with an optical density of 6 and above.

- NOTE: Operators should wear safety glasses throughout the marking process

Protective Clothing

When using Class IV lasers, operators must wear fire-resistant clothing and take all precautions to protect the skin. This is because the skin burns when the body comes into contact with the laser beam. Also, sharp edges can cause puncture and lacerations.

Store protective clothing and glasses in separate cases or storage units to prevent scratches and contamination. Any damage will affect the protection level.

Laser Class

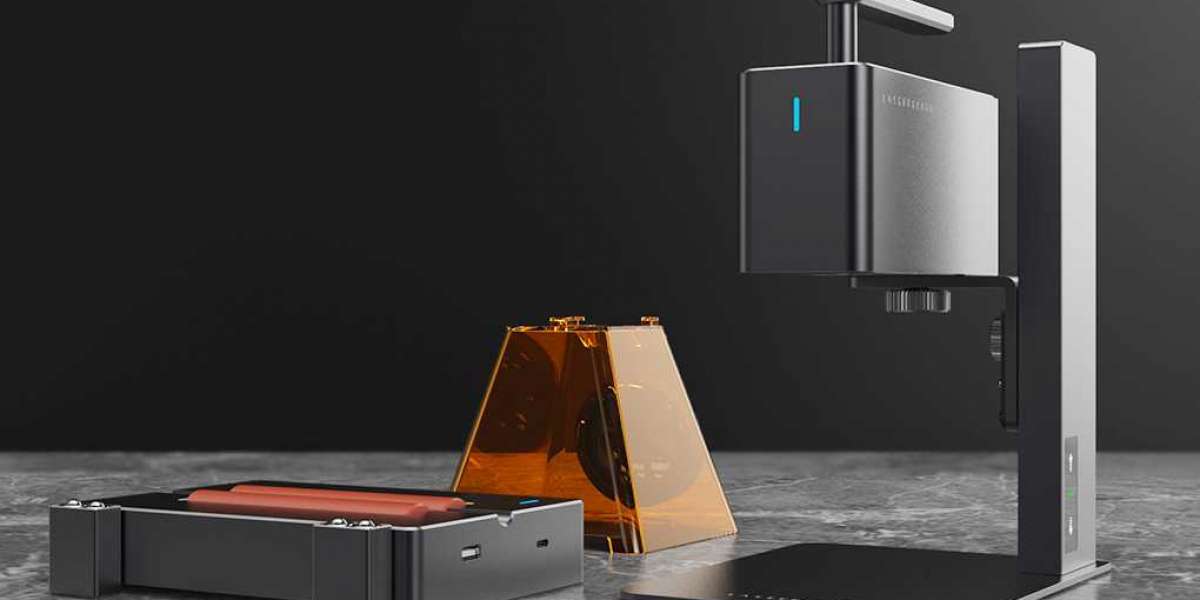

Laser marker classification is based on wavelength, power and pulse duration. The following is a classification of lasers. If you are using LaserPecker 2, I believe you don't have to consider this problem, because a shield is used in the place of the laser module, which can filter out the intensity of the laser and make it impossible for people to touch the spot of the laser.

Class I Lasers

Class I lasers have a complete enclosure that helps prevent exposure to hazardous beams, which puts their exposure limits below the maximum allowable exposure. Therefore, they are safe in normal use.

Class II Lasers

These consist of laser markings with wavelengths ranging from 400 to 700 nanometers. They are safe to use thanks to the eye's blink reflex. However, intentional viewing may cause eye damage.

Class IIIr Lasers

They are safe if handled properly. They can be dangerous in direct and specular viewing conditions, but generally not dangerous for diffuse reflections. For example, xTool D1 Pro, merchants have considered laser contact and laser reflection when designing, so many manufacturers of laser engraving machines will attach a honeycomb board to place the laser to cause harm to the human body. Of course, you'd better wear goggles. There is a double security.

Class IIIb Lasers

Power output is between 5 and 499 mW. Therefore, they can be dangerous and must include safety interlocks and key switches. Class IIIb lasers can be dangerous under direct and specular reflection. However, they are generally not harmful to diffuse reflections.

Class IV Lasers

They are potentially dangerous because direct beams are harmful to the eyes and skin. Even diffuse reflections can be detrimental. Most laser markers fall into this category and must include safety interlocks and key switches. An example is the Ortur Laser Master 3.

Overview of Laser Standards

Laser marking carries health risks. Therefore, standards must be developed to provide the necessary laser safety precautions. All standards explain the different classes of lasers, safety, precautions, laser marking, proper labelling, and how to calculate specific laser parameters.

In Conclusion

For the safety and health of employees and to avoid long-term and direct injuries, it is necessary to take safety measures when using laser marking machines. Do you need more questions about safety measures or quality machines? Please contact HTPOW customer service and staff.