The increasing usage of carbon fiber composites in aircraft manufacturing processes is fueling the demand for aerospace composites across the world. Many aircraft manufacturing companies are heavily focusing on the utilization of high-performance and lightweight structural materials for improving the fuel economy of the aircrafts and reduce their operational costs. Due to the various beneficial traits of carbon fiber composites such as high stiffness, excellent tensile strength, and low weight, they are increasingly being used for manufacturing aircrafts.

Emerging economies such as India, Indonesia, and China hold enormous potential for the growth of the aerospace composites industry players. This is because the manufacturing sector is expanding rapidly in these countries, due to the soaring middle-class population, the surging disposable income, and the rapid urbanization. Furthermore, with the growing popularity of air travel, the sales of commercial aircrafts are rising, which is, in turn, augmenting the air traffic. This is subsequently pushing up the demand for aerospace composites.

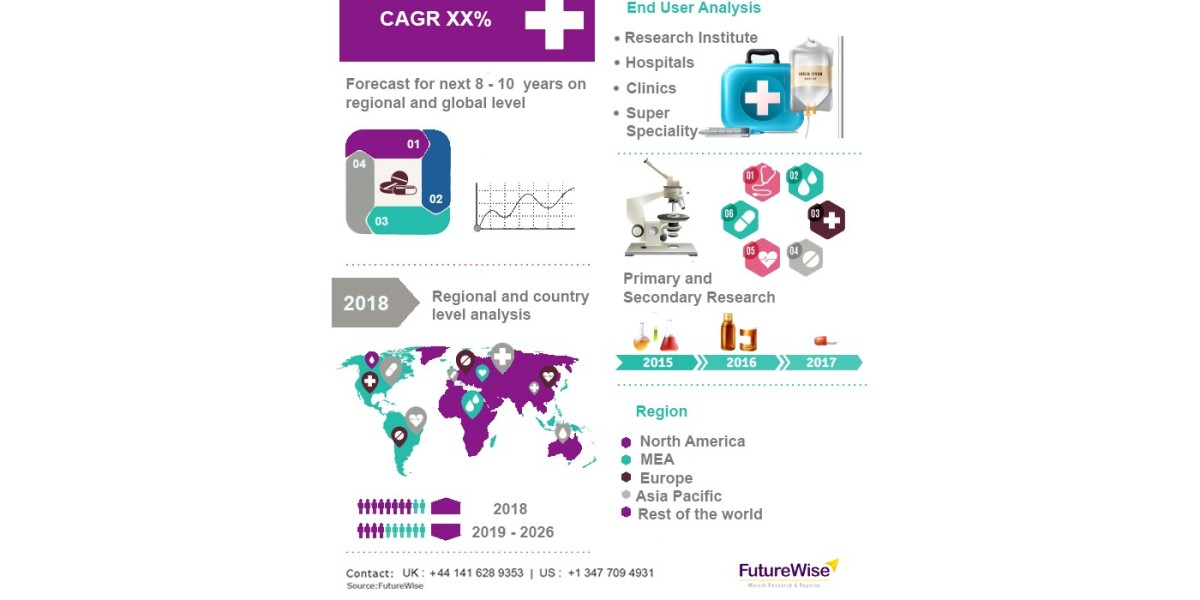

The burgeoning usage of composites in military aviation is another major factor propelling their sales across the world. This is driving the progress of the global aerospace composites market. As a result, the market revenue is predicted to surge from $2,376.7 million in 2017 to $4,234.4 million by 2023. Furthermore, the market will advance at a CAGR of 10.1% from 2018 to 2023. Aramid fiber, glass fiber, and carbon fiber are the most commonly used composites throughout the world.

Out of these, the usage of carbon fiber was found to be the highest in the world in the past years. Moreover, the sales of these fibers are predicted to rise rapidly in the coming years. This would be because of the growing requirement for these composites across the globe, on account of their various properties such as low thermal expansion and high chemical resistance. Depending on resin type, the aerospace composites market is divided into thermoplastic and thermoset.

Between these, the thermoplastic category will demonstrate the fastest growth, in terms of volume, in the market in the coming years, as per the estimates of PS Intelligence, a market research company based in India. This is attributed to the capability of thermoplastic composites to withstand very heavy mechanical loads. Moreover, these composites are widely preferred over the other variants for the manufacturing of large structural components and parts of aircrafts.

Geographically, the aerospace composites market is predicted to exhibit the fastest growth in Middle East and Africa (MEA) in the future. This is credited to the surging focus of various regional countries such as the U.A.E. and Saudi Arabia on the expansion of non-oil industries such as aircraft manufacturing to diversify their economy. To achieve this objective, Mubadala Investment Company and Solvay SA announced a joint venture in 2016 for manufacturing lightweight prepreg composite materials for aircraft parts and components.

Hence, it can be said with full surety that the sales of aerospace composites would skyrocket across the world in the forthcoming years, mainly because of the rising requirement for lightweight materials in aircrafts and the rapid growth of the aircraft manufacturing industry all over the globe.